- Categories:

- Project Update

- /

- News

Battery Conditioning for Improved Vehicle to Grid Operation

Dr Truong Bui and Professor James Marco at University of Warwick take a look at the benefits Vehicle-to-Grid technology can have on an EV’s battery health, as part of the EV-elocity project’s findings.

Introduction

Transport electrification is a key enabler to reduce fossil fuel depletion and related carbon dioxide emissions. However, critical barriers exist in terms of battery costs and their expected life.

Vehicle-to-grid technology can bring benefits to both the electrical power grid and electric vehicle owners, while its practical implementation faces challenges due to the concerns over accelerated battery degradation.

This article presents a comprehensive study on reduced Lithium-ion battery degradation through state-of-charge pre-conditioning strategies that allow an electric vehicle to participate in vehicle-to-grid operations during periods in which the vehicle is parked.

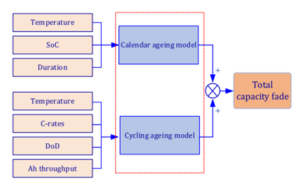

Energy capacity reduction of the electric vehicle battery are predicted using semi-empirical ageing models, which have been built and validated to capture the degradation behaviours of the battery with respect to both calendar and cycling ageing.

The analytical results show that the proposed charging strategies do not accelerate battery degradation and can mitigate the total ageing process from 7.3 – 26.7% for the first 100 days of operational life and gradually vary to 8.6 – 12.3% for one-year continual operation compared to the reference standard charging approach.

Battery Degradation

The rate of battery degradation experienced is often governed by how the battery is stored and utilised, relating to different ageing stress factors including temperature, state of charge (SoC), charge throughput, Depth of Discharge (DoD) and C-rate.

Literature shows that the causes of capacity fade can be categorized into two broad groups; calendar ageing and cycling ageing. Generally, calendar ageing is mostly affected by the battery storage temperature, SoC and time which represents how long the battery is placed in storage or in a resting state. Conversely, cycling ageing is typically influenced by ambient temperature, number of charge cycles or charge throughput, C-rate and DoD.

Battery Ageing Model

In this study, a calendar and cyclic ageing models were parameterized and validated from an experimental dataset that encompasses the envelope of operation for many real-world electric vehicle use-cases in terms of ambient temperatures, SoC and charge / discharge C-rates.

Different Charging Strategies:

An overview of five different SoC preconditioning schemes are described as follows:

- Standard charge strategy (STD CHA): EV battery is fully charged as soon as it is connected to the charger, then left at 100% SoC until departure.

- Time-shifted charge strategy (TS CHA): EV battery is left at SoC and is charged at appropriate time to be 100% at departure.

- Battery pre-conditioning using V1G (SC V1G): EV battery is left resting at SoC (or an SoC with smaller calendar aging rate), then charged at an appropriate time to be 100% at departure.

- Battery pre-conditioning using V2G (SC V2G): EV battery is discharged to the SoC with lowest calendar aging rate, then charged at an appropriate time to be 100% at departure

- Combined smart charge V1G and V2G (SC VxG): A combination of SC V1G and SC V2G that considers the trade-off having extra cyclic aging to achieve optimal SoC vs reduction of calendar ageing at optimal SoC.

Results (Subset)

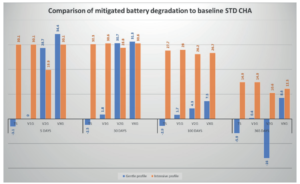

Caption: Comparison of impact of different charging strategies on battery degradation

A subset of results is summarised in the above figure showing a comparison to the baseline STD CHA strategy. It can be seen that some of the pre-conditioning strategies improved battery life when operating with a gentle driver profile (blue), due to the higher starting SoC. However, SC V2G appears to degrade the battery faster due to increased charge throughput with an increased 16% capacity loss after one year. Nonetheless, the SC VxG strategy did deliver an improvement in battery life because it balances both ageing of the SC V1G and SC V2G, resulting in an 8.6% of battery degradation after one year.

For the intensive driver profile (orange), all preconditioning strategies improved battery life significantly (10.6 – 14.9%). The TS CHA provided the most gain (14.9%) over one year for this cell type with least complexity. SC V1G and SC V2G strategies demonstrated the advantages in reducing the ageing rate of the battery while the SC VxG strategy demonstrated its capability in balancing the performance of SC V1G and SC V2G to achieve the best performance.